RC Submarine: WTC

I have chosen to build my own WTC (Water Tight Cylinder), from parts that I have brought on Ebay. At first I was only able to find a tube with an outside diameter of 60mm, but later I found a 70mm tube also. The larger tube is needed for the piston (see dive system) or the piston would else have taken up to much space. The bigger tube has also made it easier to find a suitable motor (see motor). I will also upgrade the other tube to the larger one, as it will make it easier to fit the servos later.

- A Plexiglas tube with ø= 70mm and 3mm thick. (It should be able to withdraw more than 2 bar!)

- Tube ends are made of acryl on my lathe (see picture)

- O-rings

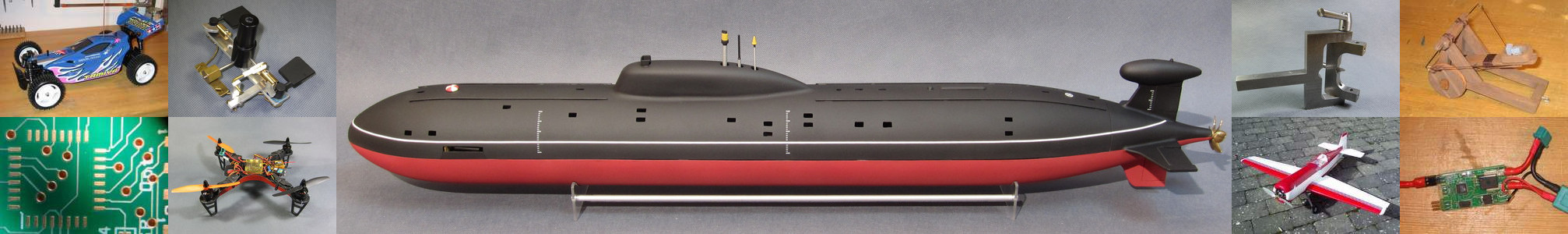

Here are some pictures of the parts so far:

Tube end fabrication

Tube end:

Complete tube with end (small tube):

Motor seal

In order to avoid that the water to enter the WTC, all rods that are exiting the tube most go through a water tight seal. The seal for the motor shaft is made from 2 O-rings inside a cylinder.

Note that the 'rod' is not the real shaft, just a rod for illustration.

The O-rings have different sizes - the small one for sealing and the large one to protect the lubrication of the small.The whole seal can then be screwed info the WTC end.

When the seal is tested with the motor the following observations are made:

- The seal is water tight

- It draws 2A more in power

- The seal is getting warm

The seal is then changed slightly: one of the O-rings is removed and the tolerances are made larger (the axle runs more easily):

- The seals is now just water tight

- It draws 1A more in power (1A less than before)

- The seal is getting warm

The seal will probably not get that warm in the water because of the great cooling.

After a little research on the internet I just realized that an O-ring the NOT suitable for a rotation seal! Here I gave up and bought a special watertight seal called a Simmering and then change the adapter to fit that.

The Simmering is the part in the center.

Servo seals

The push-rods also needs a sealing and here I am using a flex tube.

Again the whole seal can be screwed on and off.